INITIAL_PLASTIC_STRAIN_FUNCTION

Initial conditions

*INITIAL_PLASTIC_STRAIN_FUNCTION

coid, entype, enid, fid, multi

coid, entype, enid, fid, multi

Parameter definition

Variable

Description

coid

Command ID

entype

Entity type

enid

Entity ID

fid

ID of FUNCTION defining the effective plastic strain as function of $(x,y,z)$

multi

Treatment of multiple commands

Description

This command is used to prescribe or add initial plastic strains to elements.

Example

Multiple initial plastic strains

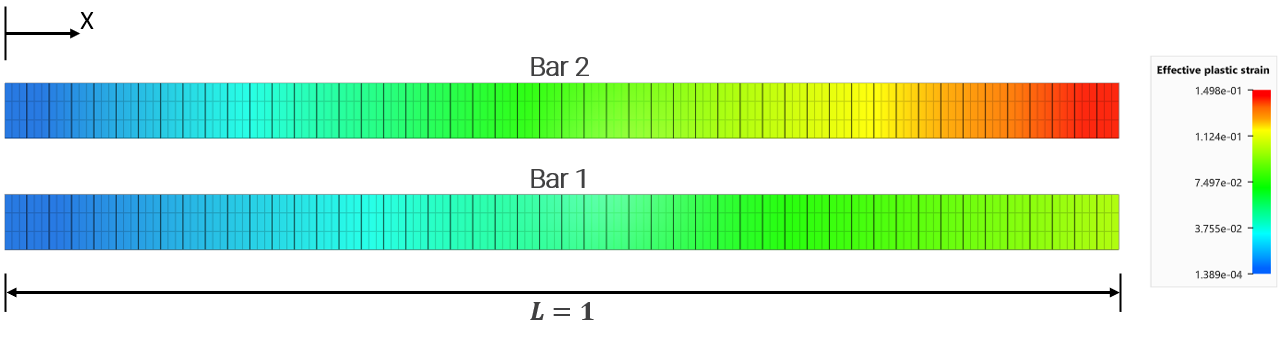

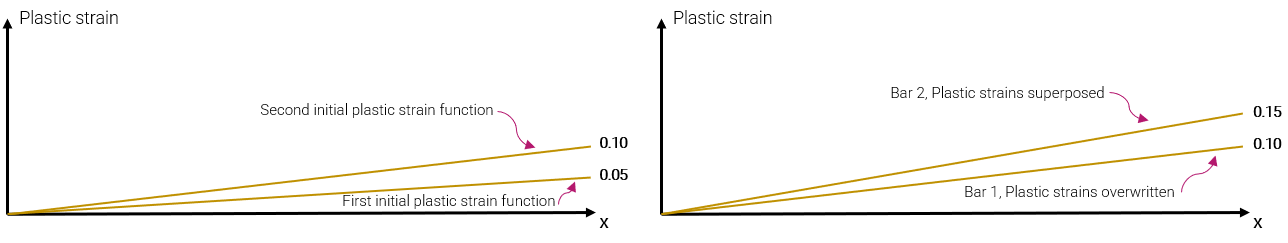

Two bars are given initial plastic strains. The plastic strains are assigned with two linearly increasing functions along their lengths. The first function goes from 0 to 0.05 and the second function goes from 0 to 0.10.

The option multi is set to 0 (plastic strains from previous commands are overwritten) for bar 1 and set to 1 (plastic strains from multiple commands are superposed) for bar 2.

*UNIT_SYSTEM

SI

*PARAMETER

%L = 1.0, "Length of bar"

%T = 0.05, "Thickness of bar"

%epsp = 0.05, "First applied plastic strain"

%epsp_2 = 0.1, "Second applied plastic strain"

%tend = 0.001, "Termination time"

#

# --- TIME and OUTPUT ---

#

*TIME

[%tend]

*OUTPUT

[%tend]

#

# --- MESH ---

#

*COMPONENT_BOX

1, 1, 50, 1, 1

0, [-%T/2], [-%T/2], [%L], [%T/2], [%T/2]

*COMPONENT_BOX

2, 2, 50, 1, 1

0, [2*%T+%T/2], [-%T/2], [%L], [%T+%T/2], [%T/2]

*CHANGE_P-ORDER

ALL, 0, 3

*MAT_METAL

1, 7800, 210e9, 0.3

1

*FUNCTION

1

100e6

*PART

1, 1

2, 1

#

# --- FIRST INITIAL CONDITIONS ---

#

*INITIAL_PLASTIC_STRAIN_FUNCTION

1, P, 1, 101, 0

*INITIAL_PLASTIC_STRAIN_FUNCTION

2, P, 2, 101, 0

*FUNCTION

101

%epsp*(X/%L)

#

# --- SECOND INITIAL CONDITIONS ---

#

*INITIAL_PLASTIC_STRAIN_FUNCTION

3, P, 1, 102, 0

*INITIAL_PLASTIC_STRAIN_FUNCTION

4, P, 2, 102, 1

*FUNCTION

102

%epsp_2*(X/%L)

*END