TRIM

Mesh commands

*TRIM

entype, enid, nid${}_{seed}$, $t_{trim}$, $\hat{x}$, $\hat{y}$, $\hat{z}$

$x_1$, $y_1$, $z_1$

.

$x_n$, $y_n$, $z_n$

entype, enid, nid${}_{seed}$, $t_{trim}$, $\hat{x}$, $\hat{y}$, $\hat{z}$

$x_1$, $y_1$, $z_1$

.

$x_n$, $y_n$, $z_n$

Parameter definition

Variable

Description

entype

Entity type

enid

Entity ID

nid${}_{seed}$

Seed node id, marking material to keep after trimming

$t_{trim}$

Trim time

$\hat{x}$

X-component of trimline projection direction

$\hat{y}$

Y-component of trimline projection direction

$\hat{z}$

Z-component of trimline projection direction

$x_1$

X-coordinate of trim line point 1

$y_1$

Y-coordinate of trim line point 1

$z_1$

Z-coordinate of trim line point 1

.

$x_n$

X-coordinate of trim line point $n$

$y_n$

Y-coordinate of trim line point $n$

$z_n$

Z-coordinate of trim line point $n$

Description

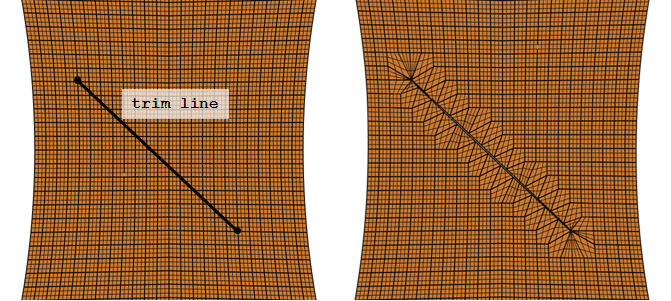

Trimming function for metal stamping applications. The trim path is a discretized line, defined by a list of coordinates. The command is only compatible with third order elements.

Example

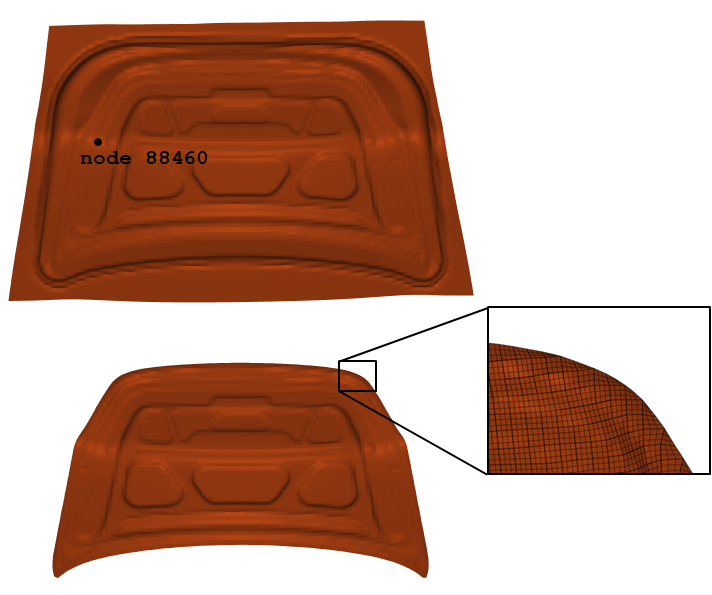

Trim 1

The following command defines a trimming operation on part 4 at time 0.2. The seed node 88460 marks the material to keep after trimming. The trim line is projected on the metal sheet in the z-direction.

*TRIM

P, 4, 88460, 0.2, 0.0, 0.0, 1.0

-0.681E+03, -0.235E+03, 0.468E+02

.

-0.683E+03, -0.249E+03, 0.371E+02

Trim 2

For lancing operation where there is no scrap material, the seed node is to be omitted. The example below is a lancing operation on part 3 at time 0.01. The cutting line is projected on the metal sheet in the z-direction.

*TRIM

P, 3, 0, 0.01, 0.0, 0.0, 1.0

-13.6, 10.2, 0.0

10.3, -12.2, 0.0