MAT_VISCOUS_FOAM

FE

Material properties

"Optional title"

mid, $\rho$, $E_1$

$\eta$, cid${}_{fe}$, cid${}_{fv}$, $c_{dec}$, $\sigma_{cut}$, $\gamma$, $\varepsilon_f$, $G_2$

$\sigma_y$

Parameter definition

Description

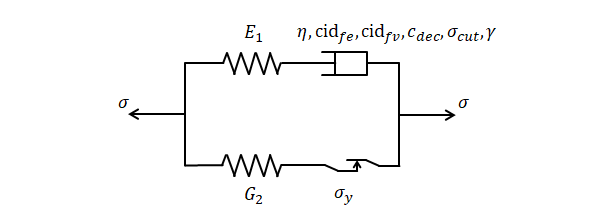

This is a model for visco-elastic foams, consisting of two networks.

Network 1

The elastic response of Network 1 is based on a formulation using the right stretch tensor $\mathbf{U}$ and its principal stretches $(\lambda_1, \lambda_2, \lambda_3)$.

$\displaystyle{ \mathbf{U} = \sum_{i=1}^3 \lambda_i \mathbf{v}_i \otimes \mathbf{v}_i}$

The total stress $\boldsymbol{\sigma}$ is the sum of an elastic and a viscous component.

$\displaystyle{ \boldsymbol{\sigma} = \left( \frac{J_{min}}{J} \right)^{\gamma} \left( \boldsymbol{\sigma}^e + \boldsymbol{\sigma}^v \right) = \left( \frac{J_{min}}{J} \right)^{\gamma} \left( \sum_{i=1}^3 \sigma_i^e \mathbf{v}_i \otimes \mathbf{v}_i + \sigma^v \right) }$

Note that the principal elastic stresses $(\sigma_1^e, \sigma_2^e, \sigma_3^e)$ coincide with the principal stretches of $\mathbf{U}$.

$J_{min}/J$ is the ratio between the smallest relative volume during the process and the current relative volume. That is, $J = \mathrm{det}\mathbf{F}$, where $\mathbf{F}$ is the deformation gradient.

The magnitude of the elastic stresses is defined from Young's modulus $E_1$, the initial porosity $\eta$ and from the compaction stress curve $f^e$. $f^e$ is basically a CURVE defining quasi-static compaction stress versus uni-axial (engineering) strain.

$\displaystyle{ \sigma_i^e = \left\{ \begin{array}{lcl} -\mathrm{min} \left( E_1 \eta_i, f^e(\eta_i) \right) & : & \eta_i \leq \eta \\ -\mathrm{min} \left( E_1 \eta_i, f^e(\eta) + E_1 (\eta_i - \eta) \right) & : & \eta_i \gt \eta \end{array} \right. }$

$\eta_i$ a measure of the compaction in principal direction $i$.

$\displaystyle{ \eta_i = \frac{\eta (1 - \lambda_i)}{\eta + \frac{1}{\lambda_j \lambda_k} - 1} }$

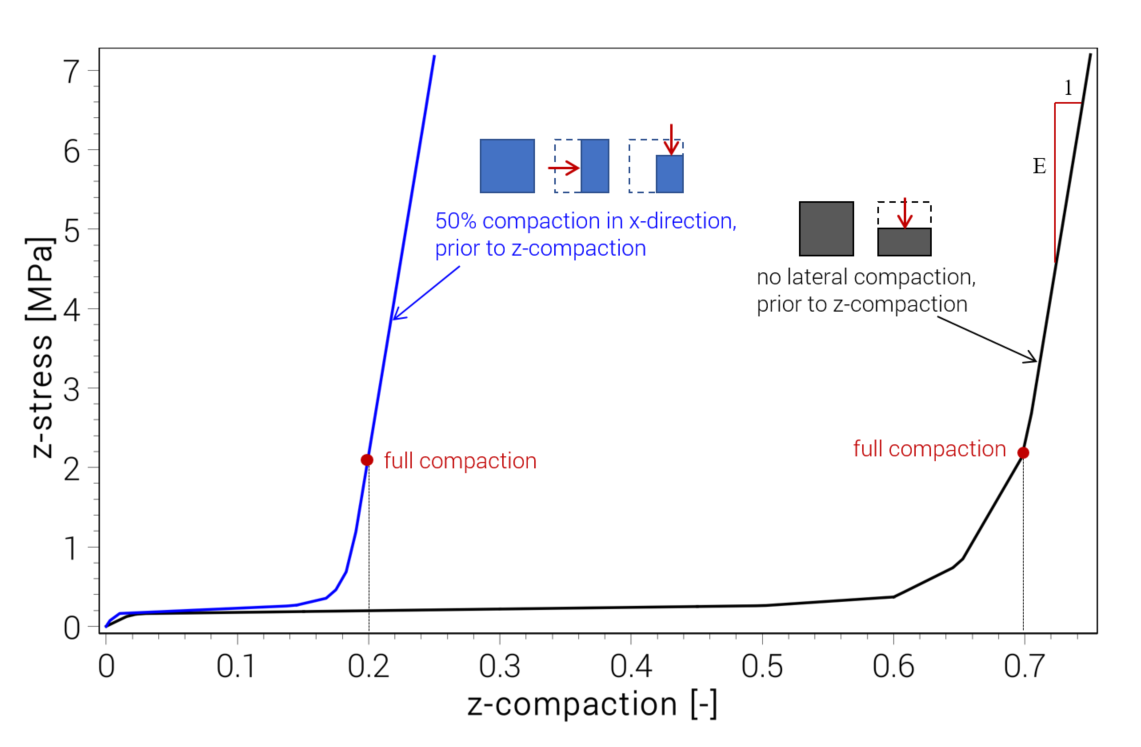

where $(i,j,k) = (1,2,3), (2,3,1)$ or $(3,1,2)$. Note that there is a coupling between the different directions. Hence, a compaction in directions $j$ and $k$ $(\lambda_j \lambda_k \lt 1)$ will decrease the porosity and, hence, reduce the room for compaction in direction $i$.

In uni-axial compression $\eta_i = 1 - \lambda_i$.

The viscous stress tensor is defined as:

$\displaystyle{ \boldsymbol{\sigma}^v(t) = \frac{1}{c_{dec}} \int_0^t f^v(\dot{\boldsymbol{\varepsilon}}) \frac{\dot{\boldsymbol{\varepsilon}}}{\vert \dot{\boldsymbol{\varepsilon}}\vert} e^{(\tau-t)/c_{dec}} \mathrm{d}\tau }$

$f^v$ is a CURVE of effective viscous stress versus effective strain rate.

Network 2

The second network is optional and it only carries deviatoric stresses. It is typically used to provide some structural integrity to the foam during unloading.

$\displaystyle{ \boldsymbol{\sigma}_2 = 2G \boldsymbol{\varepsilon}_{dev}^e }$

Yielding occurs when:

$\displaystyle{ \sqrt{\frac{3}{2} \boldsymbol{\sigma}_2 : \boldsymbol{\sigma}_2} = \sigma_y }$

Example

Quasi-static compression of foam

An example showing how compression in one principal direction affects the compression resistance in another direction.