MAT_BB

FE

Material properties

"Optional title"

mid, $\rho$, $K$

$\mu_A$, $\lambda_L$, $r$, $m$, $q$

$\mu_B$, $b_0$, $b_1$, $b_2$, $\xi$, $\sigma_y$, $\dot{\gamma}_0$

$W_c$, $\lambda_f$, erode

Parameter definition

Description

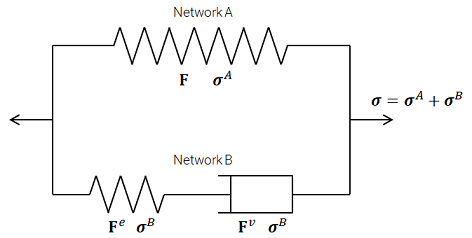

This is the Bergstrom-Boyce model for polymers. The rheological model consists of two parallell networks, here referred to as Network A and Network B.

The total stress in the material $\mathbf \sigma$ is the sum of stresses in the two networks.

$\boldsymbol{\sigma} = \boldsymbol{\sigma}^A + \boldsymbol{\sigma}^B$

Network A

Network A is hyperelastic with damage and its stress is defined as

$\displaystyle{\boldsymbol{\sigma}^A = \eta \cdot \frac{\mu}{J \bar\lambda} \cdot \frac{\mathcal{L}^{-1}\left( \bar\lambda / \lambda_L \right)} {\mathcal{L}^{-1}\left( 1 / \lambda_L \right)} \cdot \bar{\mathbf{C}}_{dev} + K \cdot \mathrm{ln}(J) \mathbf{I}}$

where $\mu$, $\lambda_L$ and $K$ (bulk modulus) are material parameters. $\mathcal{L}^{-1}$ is the inverse of the Langevin function, $J = \mathrm{det}\mathbf{F}$ and $\bar{\mathbf{C}}_{dev}$ is the deviatoric part of $\bar{\mathbf{C}}$:

$\displaystyle{\bar{\mathbf{C}} = J^{-2/3} \mathbf{F}^t \mathbf{F}}$

$\bar\lambda$ is a measure of the network stretch:

$\displaystyle{\bar\lambda = \sqrt{\frac{\mathrm{tr} \bar{\mathbf{C}}}{3}}}$

$\eta$ is an optional softening factor (Mullins). It is defined as:

$\displaystyle{ \eta = 1 - \frac{1}{r} \mathrm{erf} \left( \frac{\Psi_{max} - \Psi}{m + q \Psi_{max}} \right) }$

where $\Psi_{max}$ is the maximum specific deviatoric strain energy the material has experienced and $\Psi$ is the current specific deviatoric strain energy. Note that $r$ and $q$ are dimensionless and $m$ has the units of stress (= energy per unit volume).

Network B

Network B is visco-elastic. The deformation $\mathbf{F}$ is multiplicatively split into an elastic $\mathbf{F}^e$ and a visco-plastic component $\mathbf{F}^v$.

$\displaystyle{\mathbf{F} = \mathbf{F}^e \mathbf{F}^v}$

The stress in Network B is defined as:

$\displaystyle{\boldsymbol{\sigma}^B = \frac{\mu_B}{J^e \bar\lambda^e} \cdot \frac{\mathcal{L}^{-1}\left( \bar\lambda^e / \lambda_L \right)} {\mathcal{L}^{-1}\left( 1 / \lambda_L \right)} \cdot \bar{\mathbf{C}}^e_{dev}}$

where $J^e = \mathrm{det}\mathbf{F}^e$ and $\bar{\mathbf{C}}^e_{dev}$ is the deviatoric part of $\bar{\mathbf{C}}^e$:

$\displaystyle{\bar{\mathbf{C}}^e = (J^e)^{-2/3} (\mathbf{F}^e)^t \mathbf{F}^e}$

$\bar\lambda^e$ is a measure of the elastic network stretch:

$\displaystyle{\bar\lambda^e = \sqrt{\frac{\mathrm{tr} \bar{\mathbf{C}}^e}{3}}}$

The relationship between effective stress $\sigma^B_{eff}$ and visco-plastic strain rate $\dot{\varepsilon}_{eff}^v$ is defined as:

$\displaystyle{ \sigma^B_{eff} = b_0 (\bar{\lambda}^v - 1 + \xi)^{b_1} \cdot \left( \frac{ \dot{\varepsilon}_{eff}^v}{\dot{\gamma}_0} \right)^{b_2} + \sigma_y(\varepsilon_{eff}^v)}$

where:

$\displaystyle{ \dot{\boldsymbol{\varepsilon}}^v = \frac{1}{2} \left( \dot{\mathbf{U}}^v (\mathbf{U}^v)^{-1} + (\mathbf{U}^v)^{-1} \dot{\mathbf{U}}^v \right) }$

$\mathbf{U}^v$ is the right stretch tensor from the polar decomposition of the visco-platic deformation gradient.

$\displaystyle{ \mathbf{F}^v = \mathbf{R}^v \mathbf{U}^v }$

Damage

Damage accumulates based on two mechanisms: network stretch, $D_1$, and visco-plastic flow in network B, $D_2$:

$\displaystyle{D_1 = max\left(D_1, \frac{\bar{\lambda} - 1}{\lambda_f - 1}\right)}$

$\displaystyle{D_2 = \frac{1}{W_c}\int_0^{\varepsilon_{eff}^v} \mathrm{max}(0, \sigma^B_1) \mathrm{d}\varepsilon_{eff}^v}$

Here $\sigma^B_1$ is the maximum principal stress in Network B. The mechanisms are considered independent and the damage, $D$, is defined as:

$\displaystyle{D = min\left(1, max\left(D_1, D_2\right)\right)}$

The material will lose its shear strength when the damage, D, reaches 1.