MAT_FABRIC

FE

Material properties

"Optional title"

mid, $\rho$, $E$, $\nu$

$E_f$, $\varepsilon_l$, $\varepsilon_{f0}$, $\varepsilon_{f1}$, $\varepsilon_e$, $\sigma_y$, $K_n$, $n$

$\alpha_1$, $\alpha_2$, $\alpha_3$, $\alpha_4$, $\eta_1$, $\eta_2$, $\eta_3$, $\eta_4$

$\mu$, $\xi$, $c$, $\dot{\varepsilon}_0$, $W_c$

Parameter definition

Description

This is a model for fiber reinforced composites. Fibers can be defined in up to four different directions. Fiber stress, damage and failure is computed individually for each fiber direction.

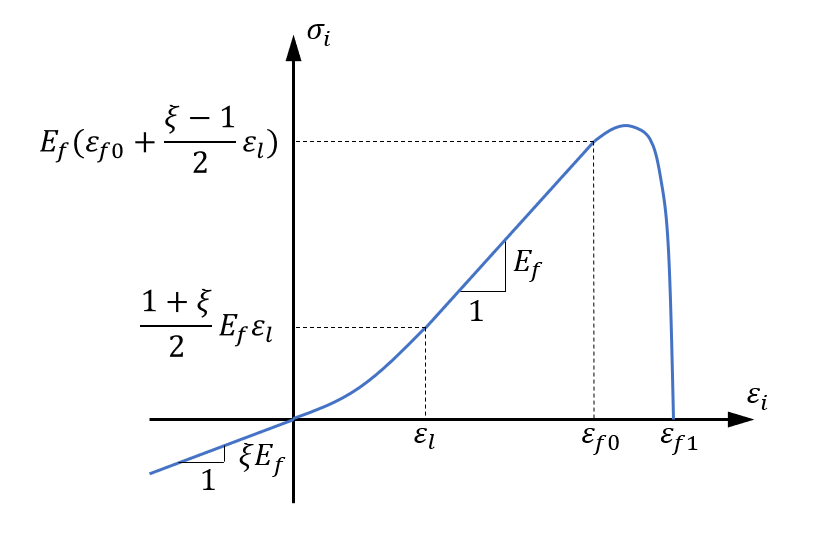

A fiber stress, $\sigma_i$, is calculated as:

$\sigma_i = \left\{ \begin{array}{lcl} \displaystyle{ sf \cdot \xi \cdot \varepsilon_i } & : & \varepsilon_i \leq 0 \\ \displaystyle{ sf \cdot \left( \frac{1-\xi}{2} \cdot \frac{\varepsilon_i^2}{\varepsilon_l} + \xi \cdot \varepsilon_i \right) } & : & 0 \lt \varepsilon_i \leq \varepsilon_l \\ \displaystyle{ sf \cdot \left( \frac{\xi-1}{2} \cdot \varepsilon_l + \varepsilon_i \right) } & : & \varepsilon_i \gt \varepsilon_l \end{array} \right. $

where:

$sf = \left(1-D_i^2\right) \cdot E_f$

$\xi$ is the ratio between initial and full tensile stiffness for the in-plane directions. $\varepsilon_i$ is the fiber strain in the direction $i$ and $\varepsilon_i$ is the locking strain. $\varepsilon_l$ is used when modeling weaves, where initial straining of the material leads to realigning of the fibers rather than strething. $\eta_i$ is the volume fraction fibers and $D_i$ is the fiber damage level which grows irreversibly from 0 to 1:

$D_i = \left\{ \begin{array}{lcl} \displaystyle{ 0 } & : & \varepsilon_i^{max} \leq \varepsilon_{f0} \\ \displaystyle{ \frac{\varepsilon_i^{max} - \varepsilon_{f0}}{\varepsilon_{f1} - \varepsilon_{f0}} } & : & \varepsilon_{f0} \lt \varepsilon_i^{max} \leq \varepsilon_{f1} \\ \displaystyle{ 1 } & : & \varepsilon_i^{max} \gt \varepsilon_{f1} \\ \end{array} \right. $

where $\varepsilon_i^{max}$ is the largest tensile strain the fibers have experienced. $\varepsilon_{f0}$ defines when fibers begin to fail and $\varepsilon_{f1}$ defines when all fibers have failed. The failure strains can be defined to be strain rate dependent:

$\displaystyle{ \varepsilon_{f0}^{sr} = \varepsilon_{f0} \cdot \left(1 + \frac{\dot{\varepsilon}_i}{\dot{\varepsilon}_0} \right)^c }$

$\displaystyle{ \varepsilon_{f1}^{sr} = \varepsilon_{f1} \cdot \left(1 + \frac{\dot{\varepsilon}_i}{\dot{\varepsilon}_0} \right)^c }$

The pressure in the material is calculated as:

$p = \left\{ \begin{array}{lcl} \displaystyle{ -K \cdot \varepsilon_v } & : & \varepsilon_v \geq 0 \\ \displaystyle{ -K \cdot \varepsilon_v + \sum_{i = 1}^4 \eta_i \cdot K_n \cdot \vert \varepsilon_v \vert ^n } & : & \varepsilon_v \lt 0 \\ \end{array} \right. $

where $K$ is the bulk modulus of the matrix and $K_n$ and $n$ are input parameters controlling the non-linear response in compression.

The total stress in the material is defined as:

$\displaystyle{ \boldsymbol{\sigma} = 2 G \boldsymbol{\varepsilon}_{dev}^e - p \mathbf{I} + \sum_{i=1}^4 \eta_i \sigma_i \mathbf{v}_i \otimes \mathbf{v}_i + 2 \mu \dot{\boldsymbol{\varepsilon}}_{dev} }$

where $\boldsymbol{\varepsilon}_{dev}^e$ is the deviatoric elastic strain in the matrix material, $\dot{\boldsymbol{\varepsilon}}_{dev}$ is the total deviatoric strain rate and $\mathbf{v}_i$ is a fiber direction.

Matrix damage evolves with plastic flow in tension:

$\displaystyle{\dot D = \frac{\mathrm{max}(0, \sigma_1) \cdot \dot\varepsilon_{eff}^p}{W_c}}$

$\sigma_1$ is the maximum principal stress in the matrix and $\dot\varepsilon_{eff}^p$ is the effective plastic strain rate. The matrix loses its ability to carry shear loads when $D=1$.

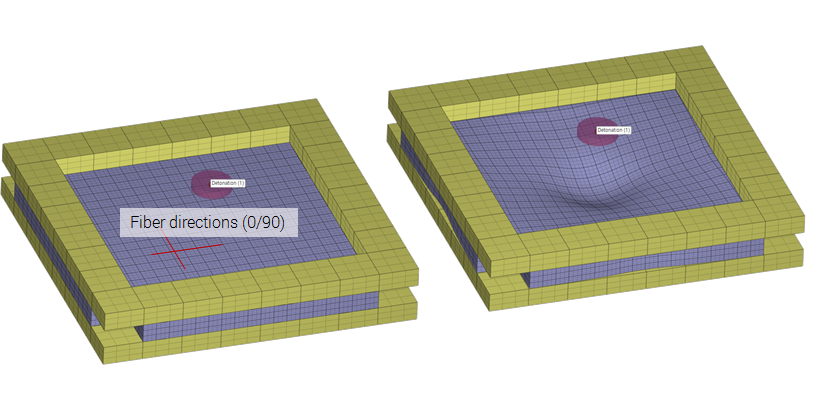

The initial fabric orientation needs to be defined using either INITIAL_MATERIAL_DIRECTION, INITIAL_MATERIAL_DIRECTION_VECTOR or INITIAL_MATERIAL_DIRECTION_WRAP.

The effective geometric erosion strain $\varepsilon_e$ is used to remove distorted elements, but it is only active for elements where all fiber directions have failed.

Example

Blast loaded Dyneema panel

Dyneema panel in a test rig exposed to blast loading.