EROSION_CRITERION_SPH_DRIVEN

Solution control and techniques

*EROSION_CRITERION_SPH_DRIVEN

"Optional title"

coid

pid, $D^{erode}$, $\varepsilon_{eff}^{p,erode}$, $R$

"Optional title"

coid

pid, $D^{erode}$, $\varepsilon_{eff}^{p,erode}$, $R$

Parameter definition

Variable

Description

coid

Command ID

pid

Part ID

$D^{erode}$

Damage threshold for erosion

$\varepsilon_{eff}^{p,erode}$

Effective plastic strain threshold for erosion

$R$

Erosion radius

Description

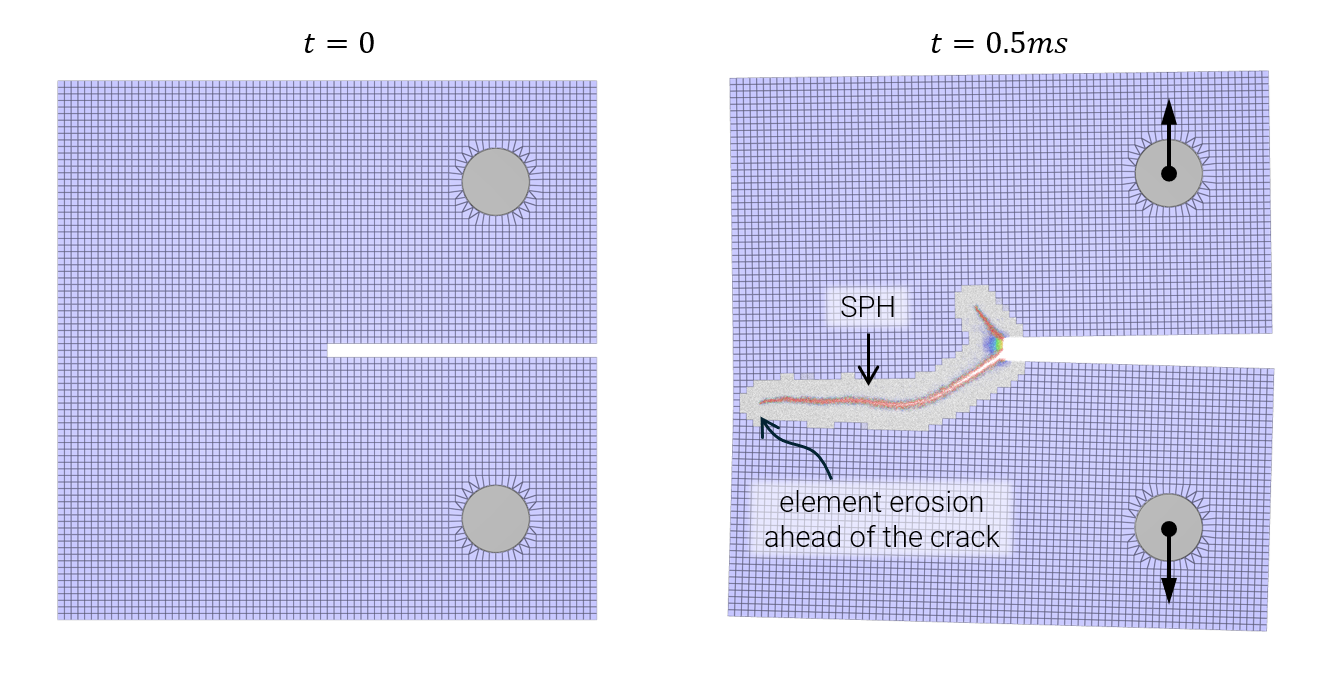

This command erodes elements based on damage or plastic strain accumulated in nearby SPH nodes. It requires that the SPH nodes have been generated using the Erode-to-SPH (E2S) procedure. The intent is to activate E2S well ahead of advancing crack fronts or regions undergoing significant plastic deformation.

Elements with centers of gravity within $R$ of an SPH node exceeding the damage or plastic-strain thresholds are eroded.

Example

Fracture toughness specimen

A model of a simple fracture toughness test specimen. Elements are eroded as the crack grows. Note that the SPH nodes have a residual strength even after reaching full damage (res_SPH$=0.01$). This prevents a local disintegration of the material along the crack.

*UNIT_SYSTEM

SI

*PARAMETER

L = 0.08, "Specimen size"

W = 0.002, "Specimen width"

R = 0.005, "Tool radius"

dx = 0.001, "Element size"

tend = 0.001, "Termination time"

disp = 0.002, "Tool displacement"

res_SPH = 0.01, "Residual strength (SPH)"

#

# --- TIME ---

#

*TIME

[%tend]

#

# --- MESH ---

#

*COMPONENT_BOX

"specimen - 1"

1, 1, [0.5*%L/%dx], [0.5*%L/%dx], [%W/%dx]

[-%L], [-%L/2], [-%W/2], [-%L/2], [-%W/2], [%W/2]

*COMPONENT_BOX

"specimen - 2"

2, 1, [0.5*%L/%dx], [%W/%dx], [%W/%dx]

[-%L], [-%W/2], [-%W/2], [-%L/2], [%W/2], [%W/2]

*COMPONENT_BOX

"specimen - 3"

3, 1, [0.5*%L/%dx], [0.5*%L/%dx], [%W/%dx]

[-%L], [%W/2], [-%W/2], [-%L/2], [%L/2], [%W/2]

*COMPONENT_BOX

"specimen - 4"

4, 1, [0.5*%L/%dx], [0.5*%L/%dx], [%W/%dx]

[-%L/2], [-%L/2], [-%W/2], 0, [-%W/2], [%W/2]

*COMPONENT_BOX

"specimen - 5"

5, 1, [0.5*%L/%dx], [0.5*%L/%dx], [%W/%dx]

[-%L/2], [%W/2], [-%W/2], 0, [%L/2], [%W/2]

*MERGE_DUPLICATED_NODES

P, 1, P, 1, [%dx/100]

*TRIM_HOLE

1

P, 1, 100, [2.02*%R], [%W]

*TABLE

100, 7

1, [-3*%R], [%L/2-3*%R], [-%W], 0, 0, 1

2, [-3*%R], [-%L/2+3*%R], [-%W], 0, 0, 1

*COMPONENT_PIPE

"tool top"

6, 2, [%W/%dx], 24, 1

[-3*%R], [%L/2-3*%R], [-%W], [-3*%R], [%L/2-3*%R], [%W], [%R]

*COMPONENT_PIPE

"tool bottom"

7, 3, [%W/%dx], 24, 1

[-3*%R], [-%L/2+3*%R], [-%W], [-3*%R], [-%L/2+3*%R], [%W], [%R]

*CHANGE_P-ORDER

PS, 23, 2

*SMOOTH_MESH

PS, 23, 45.0

*SET_PART

23

2, 3

#

# --- MATERIAL ---

#

*MAT_METAL

"brittle steel"

1, 7800.0, 210.0e9, 0.3, 1

1

0

[%res_SPH]

*FUNCTION

1

1.5e9 + 1.5e9 * epsp^0.3

*PROP_DAMAGE_CL

1

1.0e8, 5.0e4

*MAT_RIGID

"tool"

2, 7800.0

#

# --- EROSION ---

#

*EROSION_CRITERION

1

P, 1

0.9

*EROSION_CRITERION_SPH_DRIVEN

1

1, 0.8, 0, [3*%dx]

#

# --- PART ---

#

*PART

"specimen"

1, 1

"tool top"

2, 2

"tool bottom"

3, 2

#

# --- BC ---

#

*BC_MOTION

"tool top"

2

P, 2, ZX, XYZ

V, Y, 100

*BC_MOTION

"tool bottom"

3

P, 3, ZX, XYZ

V, Y, 100, -1

*FUNCTION

100

smooth_v(%disp, 0, %tend)

#

# --- CONTACT ---

#

*CONTACT

"all to all"

1

ALL, 0, ALL, 0, 0.2, 1.0e14

#

# --- SPH ---

#

*PARTICLE_DOMAIN

ALL, 0

[-2*%L], [-%L], [-%L], [%L], [%L], [%L]

*PARTICLE_SPH

"specimen"

1, 400000

1, 1, 0, 0, 0, 1

[%dx/5]

*GEOMETRY_PART

"specimen"

1

1

*END